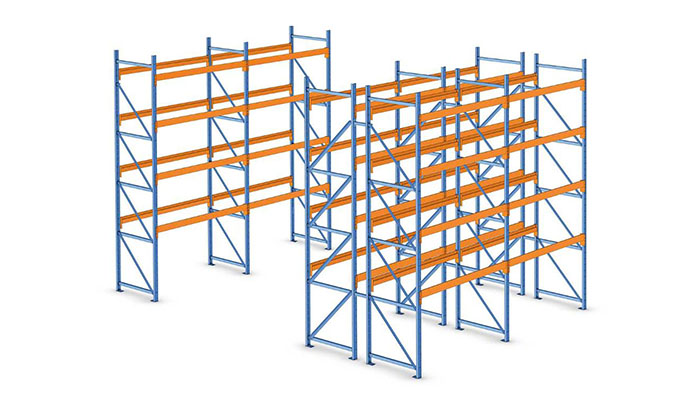

Some of the features of these racks are:

Industrial Rack Manufacturing and Fabrication Process

The characteristics that the Storage System must meet are defined in terms of load capacity and measurement of the products, as well as the dynamics of operation and the space where it will be located.

The Storage Rack System is produced and the various finishes are applied to guarantee its durability under the environmental factors of the environment where it will be located.

We ensure that your Storage System is properly assembled, including any safety and security accessories you have chosen. It is recommended to do periodic maintenance.

GET ADVICE

It is a pleasure for us to help you in your next project, leave us a message and a specialist of our team will give you free and personalized advice.